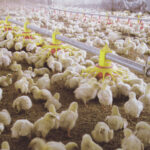

How to maintain automatic feeding equipment in poultry farming equipment?

Automatic feeding equipment in poultry farming equipment is a must in large farms. But after using it for a long time, different problems will naturally arise, and the problems must be solved. Let me solve your doubts below.

When using fully automated chicken farming equipment to feed, some farmers worry about how to ensure that the feeding system is fed evenly, whether the feed stored in the turret will deteriorate when the summer is high, and whether the bulk feeder can be equipped with metering equipment, etc.

In response to these problems, fully automated chicken raising equipment manufacturers believe that when selecting automatic poultry feeding system, the uniformity of feeding, dust generation, failure rate, and cost of accessories should be considered comprehensively. Good fully automatic chicken raising equipment has good feeding. Speed, flock stress and feed waste control design, even at high temperatures, it is unlikely that the feed will become moldy and deteriorated. However, the temperature in the feed tower is higher in summer and the feed storage time should not be too long.

Fully automatic chicken raising equipment can also reduce the labor intensity of manual feeding. The charging cart is equipped with an automatic metering device to ensure the accuracy of the ingredients.

The above is the solution to the problems in the automatic poultry feeding system shared by the poultry cage manufacturers for the farmers. I hope there is something that can help the farmers.