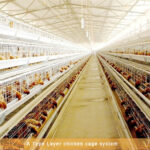

The quality standard for buying chicken cages

Chicken cages are the main cage equipment used in the chicken industry. They are the breeding methods most farmers choose now. Therefore, the quality and structural materials of the chicken cage equipment are crucial for the farmers, and it is related to whether the chickens can obtain a comfortable growth and production environment in the chicken cage. And good chicken cages can also make farmers more cost-effective, so the author will tell the farmers about the quality standards and key points of the purchase of poultry farm equipment.

First, the standard for the purchase of chicken equipment for chicken cage equipment: the general production of poultry farming equipment manufacturers, cages of chicken cages are welded by steel wire, a small number of steel wire mesh. After the mesh is formed, the chicken cage is hot-dip galvanized, and the mesh after hot-dip galvanizing is more resistant to corrosion and wear, and the service life can be greatly improved. The eggshell of the layer chicken cage is made of soft polyurethane, and the cage is pressed by A3 steel. After forming, it is galvanized.

Second, the standard for the quality of chicken battery cages:

1. After the spot welding of the cage mesh, the end of the wire should be neat, and its extension should be no more than 1 mm.

2. The cage spot welding should be firm and there must be no defects such as desoldering and breaking.

3. After the galvanized treatment of each mesh, the thickness of the hinged zinc layer should not be less than 0.02 mm.

4. The surface of the cage should be flat and no defects such as cracks and distortions are allowed.

5. The welding of the cage should be firm and no soldering or burns are allowed.

6. After the cage is galvanized, the thickness of the zinc layer shall not be less than 0.03 mm, and there shall be no leakage plating or plating peeling.

7. After assembly, the cage and cage should be straight and tidy without distortion. The cage should be perpendicular to the ground.

8. The bottom net of the cage should be straight, and the deviation of the egg gap between the egg cage and the design value should not exceed ± 2 mm. The deviation of the egg angle from the design value shall not exceed ±1°.

9. After the chicken is loaded on the bottom net, the permanent cross-section after the weight-receiving is not more than 4 mm.

The above is the material and quality standards of the chicken cage in the poultry farming equipment that the author has summarized for the farmers. If you would like to find out more, or have other questions you would like to consult, you can consult a poultry equipment manufacturer who will have a technical service to answer your questions.